The Science

Flat coin cell batteries (the kind used in watches) have been around for decades. But the combination of solid and liquid components makes it very hard to see how the components fail inside these batteries. To learn more, scientists froze an entire battery, cut it open with a super-fast laser, and took pictures of the interacting components at the microscopic scale. They wanted to know why lithium metal batteries, which should store more battery energy, fail much more quickly than standard lithium-ion batteries during reversible charging and discharging.

The Impact

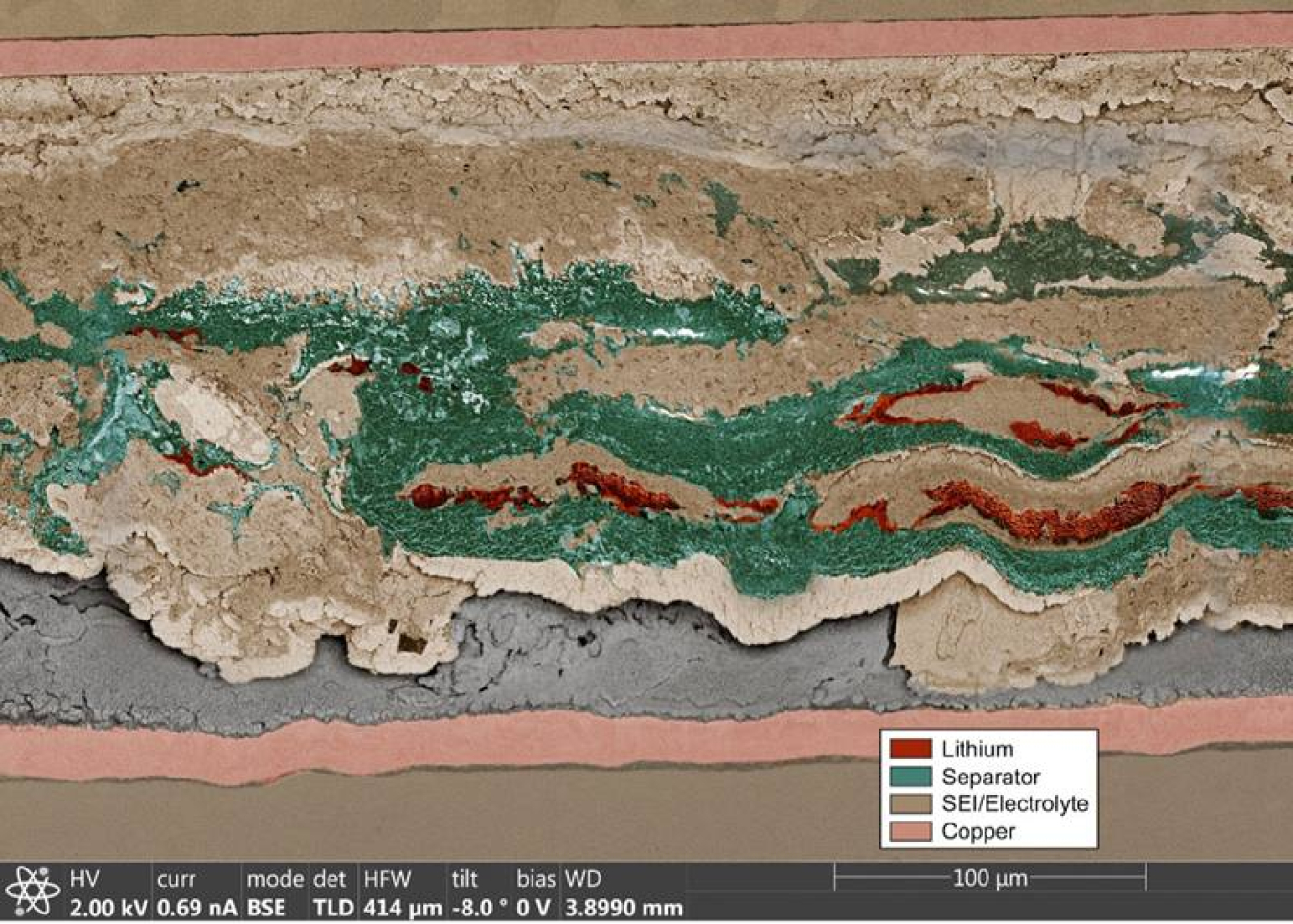

Lithium batteries using metal anodes could make future batteries smaller and lighter, but these batteries have limited rechargeability and safety concerns. One theory was that the lithium formed tough spikes (“dendrites”) that poked holes through the separator. These dendrites would convert electricity into heat and cause a fire. However, by freezing a battery and imaging it at high magnification, scientists showed that the lithium reacted with the liquid electrolyte to form solid masses that shredded the separator from the inside out. This surprising result will help engineers produce better batteries. Just as importantly, scientists can adapt this technique to reveal more mysteries that occur in other complex, solid-liquid environments.

Summary

A lithium battery stack includes two electrodes, a separator, and a cathode. These components are all soaked in a liquid electrolyte. During charging/discharging, the lithium moves back and forth between the electrodes. Lithium metal batteries enable equivalent energy storage in batteries that are smaller and lighter than current technology for portable electronics and electric vehicles, but they pose lifespan and safety challenges. Unfortunately, as the lithium metal battery charges and discharges, the mobile lithium metal interacts strongly with most liquid electrolytes, forming irregular solid masses of chemicals (“solid-electrolyte interphase” [SEI]). Previously, scientists were aware of this SEI formation, but couldn’t see the solid and liquid components without damaging them.

By freezing the entire battery, cutting it open with a laser (which cuts so quickly that it does not melt the battery), and looking at it while frozen with an electron microscope, a research team finally observed the battery failure. They observed that SEI either blocks the lithium from moving entirely (leading to short lifespan) or locks a trail of lithium in place between the two electrodes (causing a danger of fires). They also observed that the SEI forms throughout the battery, where the SEI growth destroys the separator from the inside out. This understanding is a step towards making better, safer batteries. The idea of freezing and looking inside other complex systems will also be useful in many other areas, from biomedicine to steel corrosion.

Contact

Katherine Jungjohann

National Renewable Energy Laboratory

[email protected]

Katharine Harrison

Sandia National Laboratories

[email protected]

Funding

This work was supported by the Laboratory Directed Research and Development program at Sandia National Laboratories and by the Department of Energy (DOE) though the Office of Energy Efficiency and Renewable Energy, Vehicle Technology Office, and the Office of Science, Basic Energy Sciences program. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science user facility at Sandia National Laboratories.

Publications

Jungjohann, K.L., et al., Cryogenic laser ablation reveals short-circuit mechanism in lithium metal batteries. ACS Energy Letters 6, 2138 (2021). [DOI: 10.1021/acsenergylett.1c00509]

Harrison, K.L., et al., Cryogenic electron microscopy reveals that applied pressure promotes short circuits in Li batteries. iScience, 24, 103394 (2021). [DOI: 10.1016/j.isci.2021.103394]

Related Links

The hidden culprit killing lithium-metal batteries from the inside, Sandia Labs News

Lithium-metal batteries: Direct evidence for failure, Society of Tribologists and Lubrication Engineers Tech Beat Column

Scraped from https://www.sourcearu.com